In today’s rapidly evolving business landscape, supply chain management plays a crucial role in ensuring the smooth flow of goods and services. As companies strive to optimize their operations and stay ahead of the competition, investment in warehouse technology has been a key focus. However, recent market outlook reports suggest a decline in orders for warehouse automation technology, primarily due to cost pressures and a slowdown in the global economy.

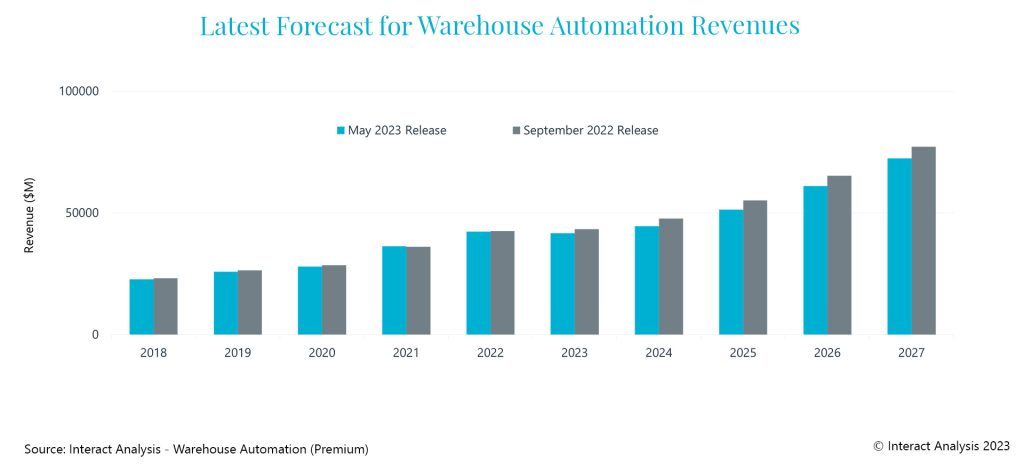

The global economy has been marked by volatility and uncertainty, leading to a revised market outlook for warehouse automation technology. Research company Interact Analysis attributes this downward revision to several factors, including excess warehouse capacity built during the pandemic, a decline in e-commerce rates, and an overall slowdown in the global economy. These factors have contributed to a decrease in the construction of new warehouses, resulting in a reduced demand for warehouse automation technology.

According to Ash Sharma, the managing director and lead for Interact Analysis’ robotics and warehouse automation division, “Our updated forecasts show the construction of new warehouses is projected to decline. In comparison to the forecast made in Q3 2022, we estimate that 6,700 fewer warehouses will be built by 2027. This reduction translates to a decrease of 1.4 billion square feet of warehousing space.”

The decline in warehouse construction is expected to have an impact on fixed warehouse automation. Annual revenues for fixed automation are projected to dip below 2022 levels. However, researchers believe that this decline will be temporary as they anticipate a rebound in warehouse construction by 2025, which will drive the demand for new automation systems.

The report highlights a downturn in automation demand among consumer-facing industries such as grocery, apparel, and general merchandise, primarily driven by decelerating e-commerce. These sectors were major drivers of fixed warehouse automation investments. On the other hand, upstream industries like food and beverage and manufacturing are expected to experience increased demand for automation systems in the short term. Factors such as near-shoring and government incentives provided in regions like the Americas and Europe have led to increased investment in automation by manufacturers. Additionally, the growth rate of food and beverage automation has also increased, with many consumer packaged goods (CPG) companies investing in new facilities.

While fixed warehouse automation may be experiencing a temporary decline, there is an uptick in demand for autonomous mobile robots (AMRs) and automated guided vehicles (AGVs), particularly automated forklifts. This shift in demand is attributed to higher-than-expected order intake in 2022 and the rapid adoption of this technology, especially in the United States where larger fleet sizes are typically adopted.

The versatility and flexibility of AMRs and AGVs make them well-suited for various warehouse tasks, such as material handling, picking, and transportation. These technologies offer cost-effective solutions for companies looking to optimize their supply chain operations without significant infrastructure investments. The ability to adapt to changing warehouse layouts and handle diverse payloads makes AMRs and AGVs attractive options for businesses aiming to improve efficiency and productivity.

As companies navigate cost pressures and seek to optimize their supply chain operations, investment in warehouse technology remains crucial. While there may be a temporary decline in fixed warehouse automation, it is essential for businesses to explore innovative tech solutions that can help overcome these challenges.

One area of focus is the adoption of advanced analytics and AI-powered systems. By leveraging data from various sources, including IoT sensors, RFID tags, and inventory management systems, companies can gain valuable insights into their operations. Predictive analytics can help optimize inventory levels, identify bottlenecks, and streamline order fulfillment processes. Additionally, AI-powered algorithms can enable dynamic routing and real-time decision-making, enhancing overall supply chain efficiency.

Another emerging trend in warehouse technology is the use of collaborative robotics, also known as cobots. These robots work alongside human workers, complementing their skills and improving productivity. Cobots can handle repetitive and physically demanding tasks, freeing up human workers to focus on more complex and value-added activities. This collaborative approach to automation ensures a balance between efficiency and human expertise, creating a harmonious working environment.

In addition to cobots, human-machine collaboration is gaining traction in the warehouse space. Augmented reality (AR) and wearable devices enable workers to access real-time information, receive instructions, and navigate the warehouse more efficiently. This technology not only enhances worker productivity but also improves safety and reduces errors.

The adoption of cloud computing and connectivity solutions is another avenue for businesses to optimize their supply chain operations. Cloud-based warehouse management systems (WMS) offer scalability and flexibility, allowing companies to adapt to changing business needs. These systems provide real-time visibility into inventory levels, order status, and overall warehouse performance.

Furthermore, cloud-based solutions enable seamless integration with other business systems, such as enterprise resource planning (ERP) software and customer relationship management (CRM) tools. This integration streamlines data flow across different departments, facilitating better decision-making and enhancing overall supply chain visibility.

As sustainability becomes a growing concern for businesses and consumers alike, warehouse technology can contribute to green initiatives. Energy-efficient equipment and systems, such as LED lighting and automated temperature control, help reduce energy consumption and minimize environmental impact. Additionally, optimizing warehouse layouts and implementing intelligent storage systems can reduce waste, improve space utilization, and lower carbon emissions.

Furthermore, the adoption of electric-powered vehicles and alternative fuels for transportation within the supply chain can contribute to a greener logistics ecosystem. With advancements in battery technology and the increasing availability of charging infrastructure, electric vehicles are becoming a viable option for companies looking to reduce their carbon footprint.

Robotics-as-a-Service (RaaS) is an emerging model that allows companies to access advanced robotics technologies without significant upfront investments. RaaS providers offer robots, software, and maintenance services on a subscription basis, enabling businesses to leverage the benefits of automation without the need for large capital expenditures. This model is particularly attractive for small and medium-sized enterprises (SMEs) that may have limited resources but still want to improve their supply chain operations.

By adopting RaaS, companies can quickly deploy automation solutions, scale their operations as needed, and benefit from ongoing technical support and updates. This flexibility and accessibility democratize robotics technology, making it more accessible to a wider range of businesses.

While cost pressures and a slowdown in the global economy may impact investment in warehouse technology in the short term, businesses should remain focused on optimizing their supply chain operations. By exploring innovative tech solutions, such as autonomous mobile robots, advanced analytics, and collaborative robotics, companies can overcome these challenges and improve efficiency and productivity. Additionally, leveraging cloud computing, embracing sustainability initiatives, and adopting robotics-as-a-service models can further enhance the effectiveness of warehouse operations. As the business landscape continues to evolve, it is crucial for companies to stay agile and leverage the power of technology to stay ahead in the competitive world of supply chain management.